Precision Excetek EDM Wire Cut Machine

The Mold and Die Industry's Secret Weapon to Perfect Molds

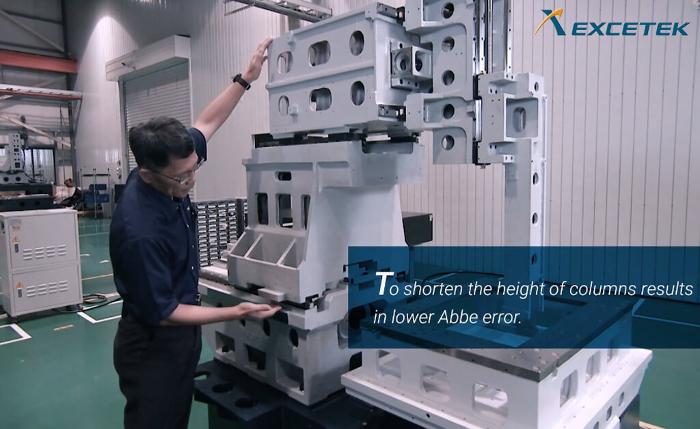

Excetek focuses on the development and innovation in the EDM sector, offering an integrated service before and after your purchase. Our professional and comprehensive product inventory provides customization services for users with full fledged EDM wire cutting machine solutions.

Wire Cutting EDM: Precision and Innovation in Manufacturing

Wire Cutting EDM (Electrical Discharge Machining) plays a crucial role in the mold and non-contact machining industries. As a leading wire EDM machine manufacturer, EXCETEK is dedicated to the development and innovation of EDM technology, offering comprehensive pre-sales and after-sales services. Our extensive product inventory provides a complete wire cut EDM machine solution, with customization options available to meet specific client needs. Whether you require an entry-level or high-end model, we provide tailored solutions that meet specific industry demands.

EXCETEK’s Vision to Wire Cut EDM Machine

Our goal is to be the most trusted partner in the mold and non-contact machining industries by providing top-quality wire cut EDM machines. We are committed to continuous development and innovation in EDM technology, delivering comprehensive solutions and customizable services to our customers. Trust stems from superior technology, consistent quality, and attentive service, all of which lead to customer satisfaction and employee fulfillment. This reliability builds strong relationships with our clients. Meanwhile, innovation drives us to constantly improve and evolve to meet industry needs.

Die Sinking EDM Machine and Small Hole Drilling EDM Machine series are also available. For more information, contact EXCETEK!

The generator & CNC Control、Mechanical Structure、Auto Wire Threading、Processing Function、Sample...

The Perfect Blend of Innovation and Precision

EXCETEK’s NP Series wire EDM machines integrate an innovative generator and CNC control system, featuring a stable mechanical structure, powerful automatic wire threading, and versatile machining capabilities. These features make the NP Series an ideal choice for those seeking both high precision and efficiency in their operations.

A Synonym for High Performance

The G Plus Series is designed for customers seeking superior performance. These EDM wire cutting machines excel in cutting speed, precision, and stability, making them ideal for industries that require high-efficiency machining. The G Plus Series ensures optimal production efficiency and top-tier product quality.

Balancing Stability and Accuracy

The VG Series wire cut EDM machines focus on achieving a perfect balance between stability and precision. Featuring a robust mechanical structure and advanced control system, this series guarantees stability during prolonged operation while maintaining exceptional accuracy. It is ideal for production environments that require continuous, high-precision machining.

Cost-Effective High-Efficiency Solutions

The V Series wire EDM machines are designed for customers looking for cost-effective yet high-performance solutions. This series maintains essential functions and reliable performance at a competitive price, making it suitable for small and medium-sized businesses or startups. The V Series allows more companies to benefit from EXCETEK’s high-quality products and services.

Customization Services: Tailored to Your Needs

Beyond our standard product lineup, EXCETEK also offers customization services to meet specific customer requirements. Our R&D and manufacturing teams focus on delivering precision and control tailored to individual needs. With user-friendly interfaces and advanced service applications, our EDM wire cutting machines enhance ease of operation and efficiency.